Partnering with Acción Performance allows your business to remain agile as production needs shift. Our customized fulfillment kitting services eliminate wasted resources by optimizing performance as we seamlessly integrate into your logistics processes.

Our Fulfillment Kitting Services

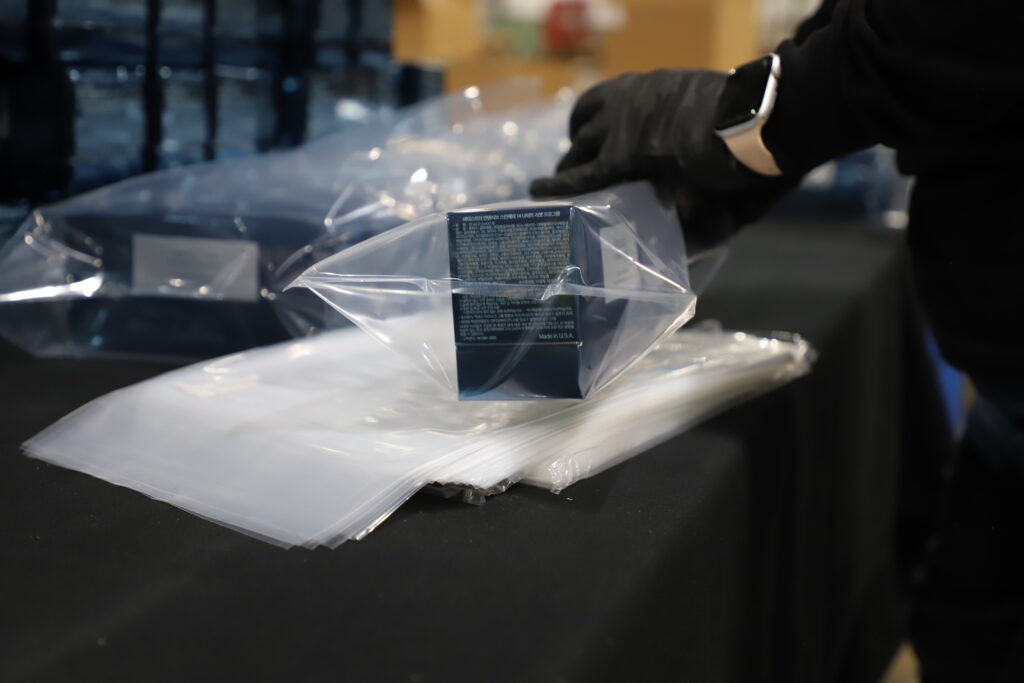

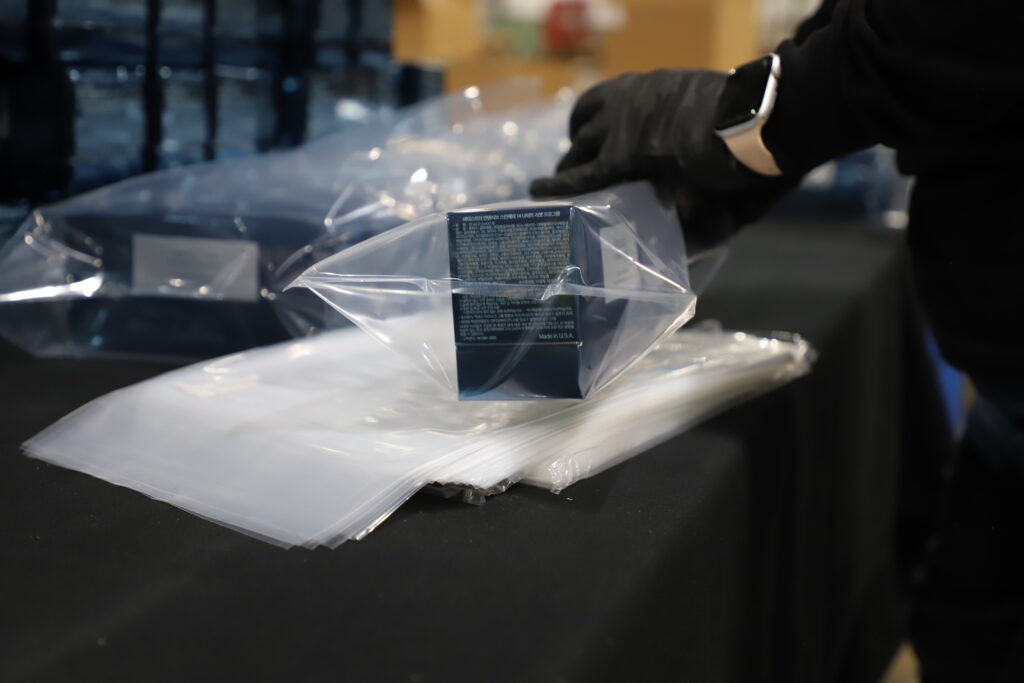

Packaging Solutions

Stay on top of product alterations and capitalize on packaging as a marketing tool to your clients. Our team can focus on product appearance while ensuring safe and secure delivery to its destination.

OUR CAPABILITIES

Assembly & Co-Manufacturing Solutions

Reduce overhead costs and boost speed to market by shifting your assembly and co-manufacturing tasks to the Acción team. Our skilled team prioritizes quality and safety at every step.

OUR CAPABILITIES

Fulfillment & Logistics Support

Improve efficiency and maintain client satisfaction by outsourcing key fulfillment operations. Our team leads will manage processes from pick and pack all the way to returns.

OUR CAPABILITIES

- Kitting and Assembly

- Primary and Secondary Packaging

- Shrink Wrap

- Labeling and Stickering

- Sortation

- Repack and Rework

- Display Builds

- Returns

- Refurbishing

Fulfillment by Amazon (FBA) Prep

Ensure your products are properly packaged and sent on time for Fulfillment by Amazon. Acción Performance prepares your items to fit necessary requirements, saving your team extra time and valuable resources.

OUR CAPABILITIES

- Packaging Solutions

-

Packaging Solutions

Stay on top of product alterations and capitalize on packaging as a marketing tool to your clients. Our team can focus on product appearance while ensuring safe and secure delivery to its destination.

OUR CAPABILITIES

- Assembly &Co-Manufacturing Solutions

-

Assembly & Co-Manufacturing Solutions

Reduce overhead costs and boost speed to market by shifting your assembly and co-manufacturing tasks to the Acción team. Our skilled team prioritizes quality and safety at every step.

OUR CAPABILITIES

- Fulfillment &Logistics Support

-

Fulfillment & Logistics Support

Improve efficiency and maintain client satisfaction by outsourcing key fulfillment operations. Our team leads will manage processes from pick and pack all the way to returns.

OUR CAPABILITIES

- Kitting and Assembly

- Primary and Secondary Packaging

- Shrink Wrap

- Labeling and Stickering

- Sortation

- Repack and Rework

- Display Builds

- Returns

- Refurbishing

- Fulfillment by Amazon (FBA) Prep

-

Fulfillment by Amazon (FBA) Prep

Ensure your products are properly packaged and sent on time for Fulfillment by Amazon. Acción Performance prepares your items to fit necessary requirements, saving your team extra time and valuable resources.

OUR CAPABILITIES

Our Capabilities

Don’t let capacity constraints keep you from reaching your operational goals. Acción Performance can quickly adjust our resources to get started on projects quickly, and exceed timeline expectations.

Managing Modern Solutions

Optimized supply chain solutions aren’t “one size fits all,” and neither are our pricing models. Our team

finds the best approach for your project to maximize your resources, including cost.

Custom Solutions

See how the Acción team creates individualized solutions for our clients across industries to optimize their unique demands.

Fulfillment Kitting Services

What is fulfillment kitting services? Fulfillment kitting services entails the process of putting together of different parts of a product or an order in a single kit. Most businesses make use of Third Party Logistics Company or 3PLs to manage their inventory of goods. The practice of fulfillment kitting services saves businesses time and also saves on their customer’s time. Fulfillment service is the third party logistics provider that helps businesses with the fulfillment kitting services by preparing and shipping customer orders on the behalf of the contracting company.

What is kitting services? Kitting is the actual process of putting together different offers into a single product. While other companies prefer the services of a third party logistics company, some businesses predict their customers’ needs and package certain products into batches ready for shipping upon order. However, the choice depends on the nature of products and company size. All in all, it is not always logical to kit items, but consulting with a 3PL will help you figure out if kitting is necessary for your products.

Ecommerce fulfillment center

Ecommerce fulfillment centers help online businesses overcome challenges of warehousing and shipping. These services are more critical for smaller online businesses with limited storage space and staff to manage inventory. Online fulfillment centers, therefore come in to save online businesses the strain. Truly, without online fulfillment centers some online businesses would not exist.

Ecommerce fulfillment centers provide the critical warehousing/storage and shipping services that ecommerce businesses outsource. By outsourcing these services, the ecommerce business can concentrate on marketing and selling while delivering the best customer experience to their clients within the stipulated time.

Ecommerce fulfillment centers not only help with shipping and warehousing but also have other significant benefits to online businesses. It also helps in curbing the problems of overselling, whereby the business sells more products than they have in stock- this reflects badly on the business and attracts negative customer reviews which most online businesses rely on to attract customers. Other problems ecommerce merchants overcome with outsourcing online fulfillment center services are mis-ship which can lead to extra costs to the business.

Kitting definition

Kitting is a warehouse and shipping strategy; widely used with the rising popularity of online businesses. It applies in businesses like Amazon, ecommerce marketplace and other large retail chains. The kitting strategy involves sourcing of different products that go together or are purchased together and packaging them into a singles kit using kitting equipment. Therefore, kitting is an inventory technique for packaging and shipping items in bundles.

In logistics, kitting strategy helps in streamlining the shipment process. It also lowers the shipping costs and fastens the process of order fulfillment enhancing the levels of customer satisfaction. A kitting company will collect the different products and bring them together for packaging. The kitting company will then use the seller’s branded kitting equipment to pre-package and pre-label the product before shipping to the client. As a result, the items appear as though they originated from the same destination.

The kitting process

The kitting process requires the bringing together of the different products and placing them under a single kit unit in the system for sale. The process involves the following key steps:

- First you need to identify the different items that should go into the kit based on their qualities such as the use of product, color and theme among other qualities.

- Secondly, you need to assign the single kit unit number (SKU number) to the newly assembled bundle. It is best to track the individual items separately without selling each kit as an item for proper tracking of sales trends and inventory.

- Thirdly, assemble the items and relocate the assembled kits to warehouse for easy bundling to save on time and money.

- The final step is selling and shipping the items as bundles, and watching your profits.

The kitting process flow chart

Kitting process in warehouse

For efficacy, kitting process in warehouse is done as other shipping operations and procedures, and doesn’t require extra staff and equipment. The only areas that require adjustment are the procedures of picking products and engagement with workflows.

Kitting process in manufacturing

Kitting process is also applied in manufacturing process. The manufacturer organizes and assembles parts used in the production of items in bundles; which they then deliver to areas required for use. Kitting process in manufacturing helps the manufacturer in the following ways:

- Reduction of warehouse costs

- Streamlines packaging and shipping process

- Helps in performance of inventory and tracking

- Helps in controlling manufacturing and inventory

Fulfillment center processes and flow

There are certain areas you need to pay close attention to in the kitting process for fulfillment center processes and flow:

- Ensure accurate branding by use of private labelling

- Proper packaging to preventing damage of items on transit

- Accuracy in assembling the products

Kitting services near me

Now that you are aware of kitting services meaning, you can evaluate if your business needs them or not. You can, therefore, do a quick Google search of kitting services near me. From the results you can identify and contact the company that you feel best suited for your needs. Chances are that you will find one that will offer the packaging and kitting services you require.

First, contact the kit assembly service provider and discuss with them about your business and products. Hear them out and ask for their opinion on the possibility of packaging and kitting services for your goods. From there you can draw an agreement and focus on selling without worrying about the warehousing and shipping.

Kitting in warehouse

Kitting in warehouse involves taking multiple SKUs and packaging them into a new SKU. The outcome of kitting in warehouse is one single complex kit made up of different products. The same applies the branding strategy of the seller enhancing their customer service and satisfaction.

Kitting in manufacturing

Kitting in manufacturing involves the process of assembling and organizing the different parts useful in the manufacture of products and bundling them for delivery at their points of use. The outcome of kitting in manufacturing is reduces warehouse costs, and simplified packaging and shipping.

Kitting in logistics

Kitting in logistics involves putting together multiple products into a single unit for shipping. Logistic companies and businesses effectively streamline shipping processes. This is because they have the capacity and equipment to carry out the process at a lower cost and faster.

Kitting supply chain

In supply chain, kitting and fulfillment service companies come as an intermediary between the customer and the seller. The kitting company in this case helps the seller reach their customer faster in a cheaper way while providing better services. Kitting supply chain function is hard to ignore in the present business world as it does not only create a more effective network but also streamlines ecommerce logistics.

Kitting and assembly

Most third-party logistics (3PL) offer kitting and assembly services. These fulfillment services involve the packaging of items arriving separately into single grouping as they anticipate customer orders. They also ship the products upon order by customers. Outsourcing kitting and assembly solutions has helped small business serve markets they would have otherwise been unable to reach. The main objective behind investing in the services of kitting and assembly solutions companies is the aspect of convenience. The seller delivers consistently high timely quality products.

Prep it pack it ship it

The main roles of fulfillment service companies are “prep it pack it and ship it”. Among parts kitting best practices is time efficacy. Customer need to be assured that their ordered goods are available when needed. There is also need for accuracy in packaging and labelling of products for maximum customer satisfaction. Fulfillment service companies, therefore, need to ensure parts kitting best practices since a bad image to the selling business translate to loss of business to the kitting and fulfillment service company.

As we saw earlier, without the services of fulfillment and kitting companies, it would be impossible for small ecommerce businesses to prep and ship their orders to customers at different localities. Some items that require kitting fulfillment include electronic equipment and furniture that require assembling after shipping. If you are looking for a job in the fulfillment kitting services, you can search up different roles advertised on indeed. You can check out the advertised opportunities on their website https://www.indeed.com. Indeed advertises thousands of job opportunities it would be almost impossible to miss a match for you.