Partnering with Acción Performance allows your business to remain agile as production needs shift. Our custom order picking operations solutions to eliminate wasted resources by optimizing performance as we seamlessly integrate into your logistics processes.

Order Picking Operations Services

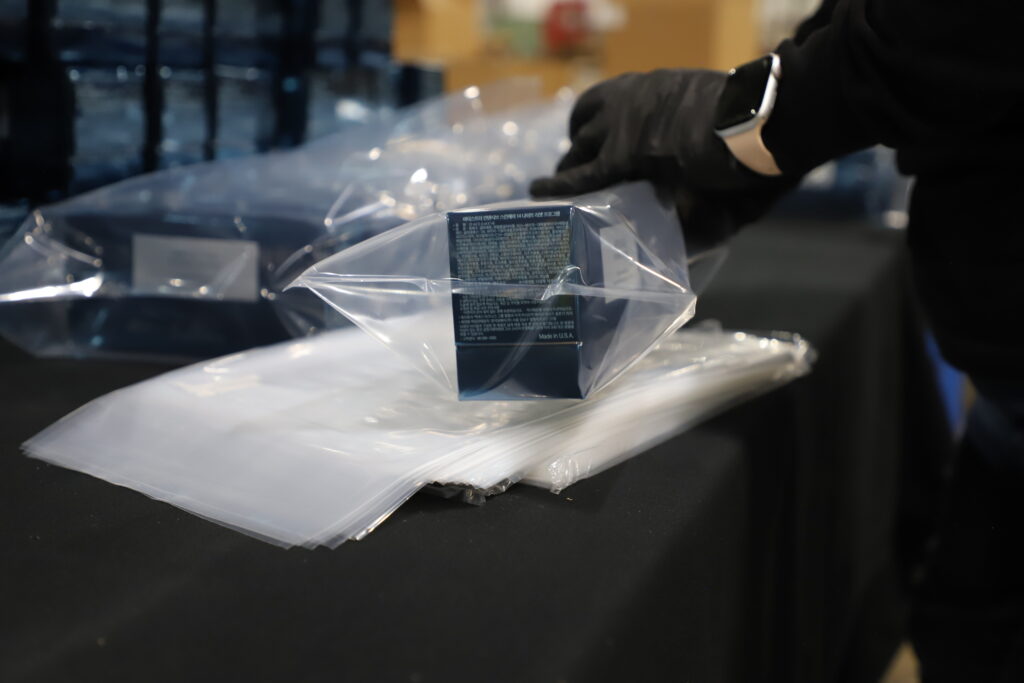

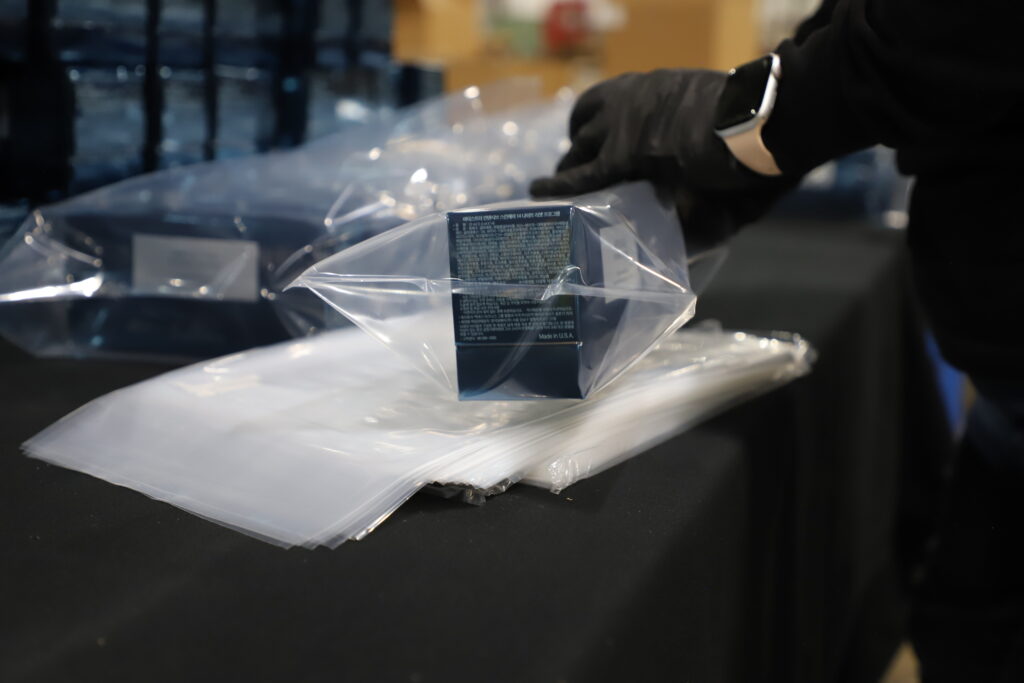

Packaging Solutions

Stay on top of product alterations and capitalize on packaging as a marketing tool to your clients. Our team can focus on product appearance while ensuring safe and secure delivery to its destination.

OUR CAPABILITIES

Fulfillment & Logistics Support

Improve efficiency and maintain client satisfaction by outsourcing key fulfillment operations. Our team leads will manage processes from pick and pack all the way to returns.

OUR CAPABILITIES

- Kitting and Assembly

- Primary and Secondary Packaging

- Shrink Wrap

- Labeling and Stickering

- Sortation

- Repack and Rework

- Display Builds

- Returns

- Refurbishing

- Packaging Solutions

-

Packaging Solutions

Stay on top of product alterations and capitalize on packaging as a marketing tool to your clients. Our team can focus on product appearance while ensuring safe and secure delivery to its destination.

OUR CAPABILITIES

- Fulfillment &Logistics Support

-

Fulfillment & Logistics Support

Improve efficiency and maintain client satisfaction by outsourcing key fulfillment operations. Our team leads will manage processes from pick and pack all the way to returns.

OUR CAPABILITIES

- Kitting and Assembly

- Primary and Secondary Packaging

- Shrink Wrap

- Labeling and Stickering

- Sortation

- Repack and Rework

- Display Builds

- Returns

- Refurbishing

Our Capabilities

Don’t let capacity constraints keep you from reaching your operational goals. Acción Performance can quickly adjust our resources to get started on projects quickly, and exceed timeline expectations.

Managing Modern Solutions

Optimized supply chain solutions aren’t “one size fits all,” and neither are our pricing models. Our team

finds the best approach for your project to maximize your resources, including cost.

Custom Solutions

See how the Acción team creates individualized solutions for our clients across industries to optimize their unique demands.

Order Picking Operations

We live in a digital age, and it has become increasingly necessary for businesses of all sizes to streamline their warehouse order picking operations. It is especially true for organizations that rely on warehouse staff or automated equipment to fulfill orders. An order picker makes everything more comfortable and practical. For instance, with an order picker Raymond, you get to maximize the service level subject to resource constraints such as labor, machines and capital.

Facility managers and business owners should rely on excellent picker tips as they can make or break efficiency in a warehouse operation. If you are beginning to learn how to improve picking accuracy in warehouse, you should consider choosing the proper order picker. Order picking and service level are closely linked since if an order can be retrieved fast, it can be shipped expeditiously to the customer. For instance, you won’t have to worry about orders missing their shipping due time with an order picker Raymond. It would help if you had an optimized order picking system, and it all starts with learning how to improve picking accuracy in the warehouse.

Order picking in warehouse

Order picking in warehouse is a simple concept but can be pretty complex. To put it in simpler terms, order picking in warehouse is the necessary labor and parts that play a role in pulling an item from the inventory, all to fulfill a customer’s order. You will need the proper order picking systems if you want to achieve efficiency within your warehouse. The process might sound like the most uncomplicated process, but when you look at the numbers and see how ineffective order picking equipment can stop innovation, you should think twice.

If your business fulfills orders, you must consider order picking systems that emphasize speediness, accuracy and organization. Generally, order picking falls under warehouse logistics. It also includes the order picking software and automated order picking systems. Once you streamline your order picking in the warehouse, especially with the correct order picking equipment, you can rest assured that you will offer your customers faster order fulfillment. Likewise, with order picking software, you can promote automation. When you have automated order picking systems, you get to minimize cost and maximize asset utilization.

Batch picking

Batch picking in warehouse is one of the best strategies any warehouse can employ, especially where pickers need to travel long distances to fulfill multiple orders with the same SKU. If your warehouse chooses to use this order picking strategy, your pickers will be required to select a group of orders simultaneously but one product at a time. If you compare wave picking vs batch picking, it helps to note that wave picking involves pickers fulfilling orders by picking one SKU at a time. It makes a whole lot of sense if your warehouse is struggling with high fulfillment demand along with plenty of diverse inventory.

However, if you use the batch picking strategy, your warehouse manager will need to assess the current orders for popularity and place them into sets depending on their SKU. The batch picking type of goods will be where the pickers are best located to get the orders fulfilled within the shortest time possible. Batch picking strategy lifo works incredibly well for e-commerce businesses with predictable ordering trends. If you specialize in food and apparel, the batch picking strategy should work out for you.

Warehouse picking strategies

Warehouse order picking strategies should be customized to meet the business’ unique fulfillment needs. Sometimes, the method you choose can be determined by your warehouse picking equipment and its size. If you are interested in the warehouse picking best practices, the strategies you should be using include zone picking, discrete picking, batch/multi-order picking, cluster picking and wave picking.

Every warehouse should consider its order picking methods. While you might have the latest warehouse picking technology, it is the most straightforward strategy that works well for small businesses. However, as your company grows and your warehouse becomes significantly bigger, you will need to look at more efficient ways of picking your orders.

Regardless of the warehouse picking strategy you choose, consider having a warehouse picking process flow chart that keeps you on track. Likewise, remember that selecting the most advanced order picking method does not necessarily mean that it will work. If you want to get the most out of the warehouse picking technology, all you need is to employ warehouse picking best practices.

Zone picking

Zone picking is an excellent warehouse picking strategy. It is mainly put into place when the warehouse compiles orders with multiple components and in large warehouses to reduce the walk times for individual pickers. Unlike cluster picking or discrete picking, the inventory is organized into zones where an order picker is stationed with the unique SKUs found only in their zone. When ordering fulfillment, bins or totes move through each location while simultaneously collecting products for multiple orders. When the bin attains the required volume, orders can be fulfilled by a putting the needed number of SKUs by a picker.

On the other hand, Cluster picking is one of the most effective types of picking in warehouse. It involves multiple orders being simultaneously compiled by a single picker. Usually, it deals with a variety of SKUs. When it comes to speed, this strategy might not be the most ideal, but you can integrate unique technologies and resources to make it work for you. In discrete picking, workers are required to compile each piece of necessary inventory one at a time. It is a plan that might work if your warehouse has a small team and does not deal with complex customer orders.

Single order picking

The single order picking definition is fulfilled by manually selecting each item directly from an open case, bin or storage box. Another single order meaning is where pickers pick items needed for one order at a time. It makes it a simple, reliable, and accurate way for businesses to complete their customers’ orders.

Notably, in single order picking, the pickers move through the warehouse and retrieve SKUs one by one to fulfill the orders one at a time. It works best for the small warehouses that handle simple orders with a few items. An excellent single order picking example is where workers in a warehouse are handed a pick lists the move around the warehouse picking out the required items one at a time.

It results in a lot of travel time around the warehouse, making it ideal only for the small warehouses. The best thing about single order picking is that it’s pretty simple, making it less expensive to implement and execute.

Warehouse inbound process flow chart

Every warehouse should know where and how products are moved, and that is where a warehouse inbound process flow chart comes in. It should be in place before the order fulfillment process begins. With a warehouse operation warehouse flow chart, you can brush up on your work and understand who you should hire and for what reason. As long as you have the right warehouse processes and procedures in place, you can rest assured that you will save your business time and money.

Your warehouse operation warehouse flow chart should define all the stages in your warehouse activities so that you can focus on getting the work done. As long as you stick to the warehouse inbound flow chart, you can rest assured that your warehouse picking error rates will be significantly low. If you find a way to integrate the different types of low charts into your business, you will streamline your operations and get to the levels you hope to get to.

Is order picking hard?

If you own a warehouse, you will be asking if order picking is hard. The answer is yes and no. Yes, if you have challenges making your numbers, if you do not understand the layout of your warehouse, you have trouble operating order picking equipment and dealing with a repetitive routine. On the other hand, order picking can be something you can handle comfortably. All you need is the proper order picking equipment and follow the best strategies. Knowing what you are doing can make a real difference.

Hard or not, the importance of order picking is something you can’t turn a blind eye to. It is an essential aspect within any warehouse, forming 55% of operations costs compared to shipping, storage and receiving stages. What’s more, it has a direct impact on customer satisfaction levels. Suppose you are not yet convinced about the importance of picking process in warehouse. In that case, you need to understand that quickly and accurately processing customer orders has become an essential part of doing business. You will never get to the levels you are hoping for if you don’t have a reliable order fulfillment process.

Since order picking is the most labor-intensive activity in the warehouse, it is your responsibility to choose the best systems to make work more comfortable. Likewise, the strategy you opt for will have a significant role to play.